Originally, laver farming depended on natural conchospores (seeds) until Kathleen Drew Baker, British phycologist discovered the life cycle of Porphyra in 1949. This was a great contribution to the laver farming industry, which enabled artificial production of seeds.

-

Mid May

The farming fist stage occurs indoors. Laver’s carpospores are reared in water tank and their microscopic filaments bore into oyster shells (conchocelis phase). The water temperature is controlled optimum conditions to encourage vegetative growth of the conchocelis phase until the timing of conchospores release. This is one of the most important process affects the quality of final product.

-

September

Prepare poles (bamboo or glass fiber pole) in the laver farm. About 55-66 poles are to be planted to hang 8-10 laver nets which is 20 meter long and 1.8 meter width each.

-

Early October

The laver nets are prepared in 30 layers and suspended about 30 bags containing 1-2 oyster shells each.

-

Spread nets in the laver farm and attach to the poles.

-

30 layered nets with bags suspended. The conchospores in oyster shell are release in the water and attach to the nets at high tide. This procedure calls “collecting seeds”.

-

After 2-3 days, remove bags and await laver to grow. The cultivators spray seawater on the nets to enhance laver to grow and to wash off any dirt periodically.

-

When the laver reach 2-3 cm long, half of the nets (15 layers) are brought back from the sea, dried and refrigerated. These are the reserved nets in case of diseases or trouble in future cultivation process.

-

Refrigerated nets stored in minus 25 degree.

-

Remaining nets in the laver farm are spread into single layer to enhance further growth. These nets are called “Autumn laver nets” in distinction from the one refrigerated.

-

When laver reaches 15-20 cm long, the first harvesting phase begins. This is called “Autumn first harvesting”. These lavers are nutrient-rich including amino acid produced by photosynthesis with sufficient sunlight. These are soft, slight sweetness in taste and dark reddish in color.

-

The cultivators start harvesting activities before sunrise. It is said that the nutrient will be drawn out of the cells once the laver begins photosynthesizing in the sunlight.

-

Small harvesting boat shuttles between harvest field and mother boat and pump the laver.

-

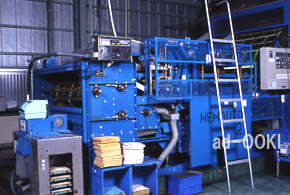

Harvested laver is dried and processed in the machine at the cultivators’ workplace. The final product (NORI) is sorted by condition, packed and carried to the cooperative association quality inspection center.

-

At quality inspection center, they run rigid inspection and grading, then delivered to the cooperative market.

-

November – March

NORI auction is held at each regional cooperative market. Only the members with bidding qualification are allowed to participate.